Capabilities

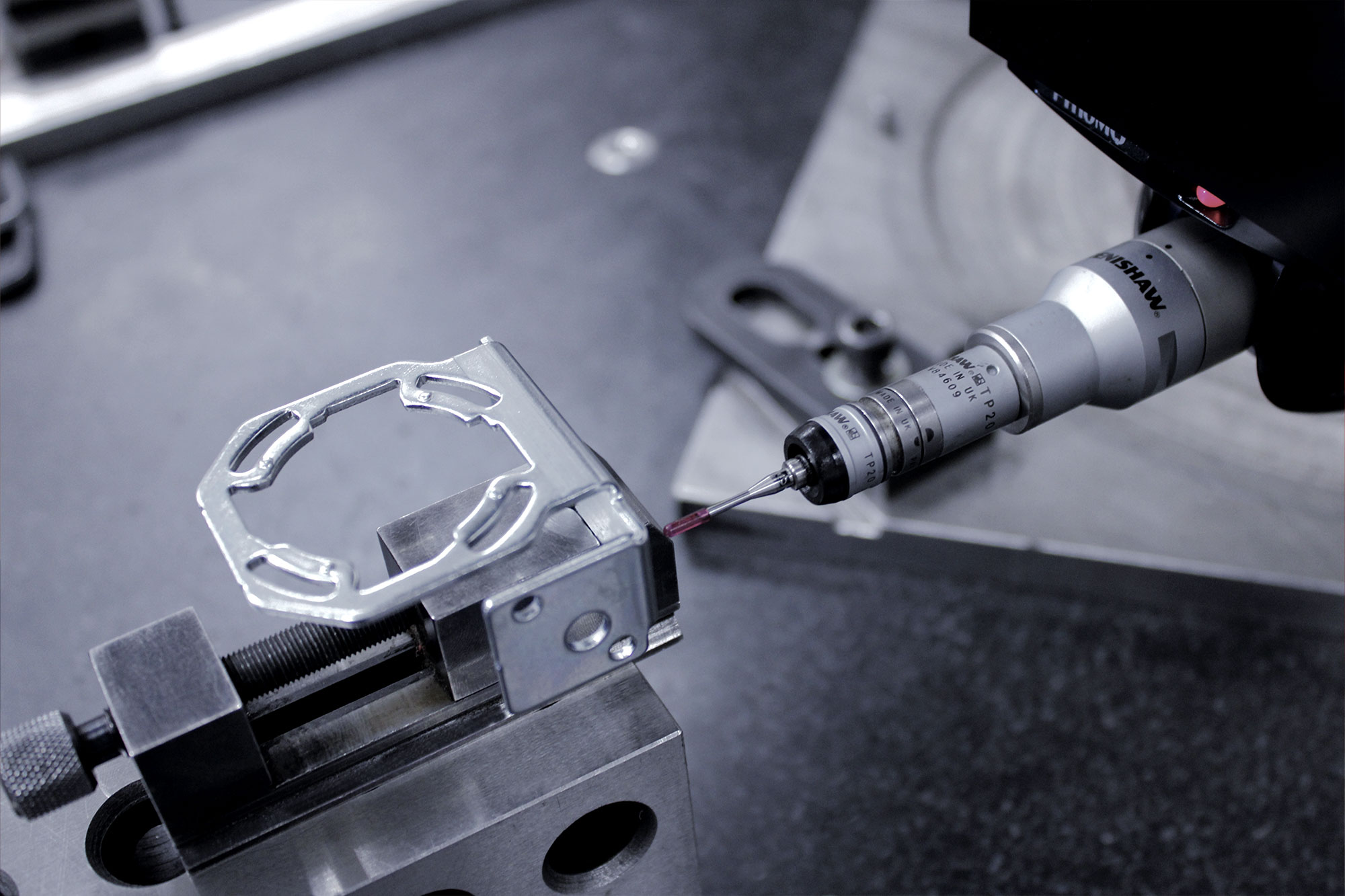

As an ISO 9001:2015 certified company, Accord Manufacturing provides products and services to the highest standards, proudly made in the USA. Our quality team will work with you from FAI/PPAP through your ongoing production requirements.

At Accord Manufacturing, quality is always a priority in any metal stamping or fabrication job we accept. We continuously strive to produce the highest quality precision metal parts.

Our team is dedicated and committed to quality, and with the latest, up-to-date inspection equipment in our lab, we can assure you that your parts are made precisely to the specifications you require. Let us use our 35+ years of experience in tin stamping, fabrication, and engineering to work for your organization today.

Along with a variety of standard mechanical inspection equipment, Accord Manufacturing also has the following in our quality lab:

- Hexagon Global S Blue CMM with PC-DMIS software

- Hexagon 85 Measurement Arm

- Mitutoyo SJ-410 Surface Roughness Tester

- Mitutoyo HR-400 Hardness Tester

- Starrett HB-400 Precision Optical Comparator

Stamping

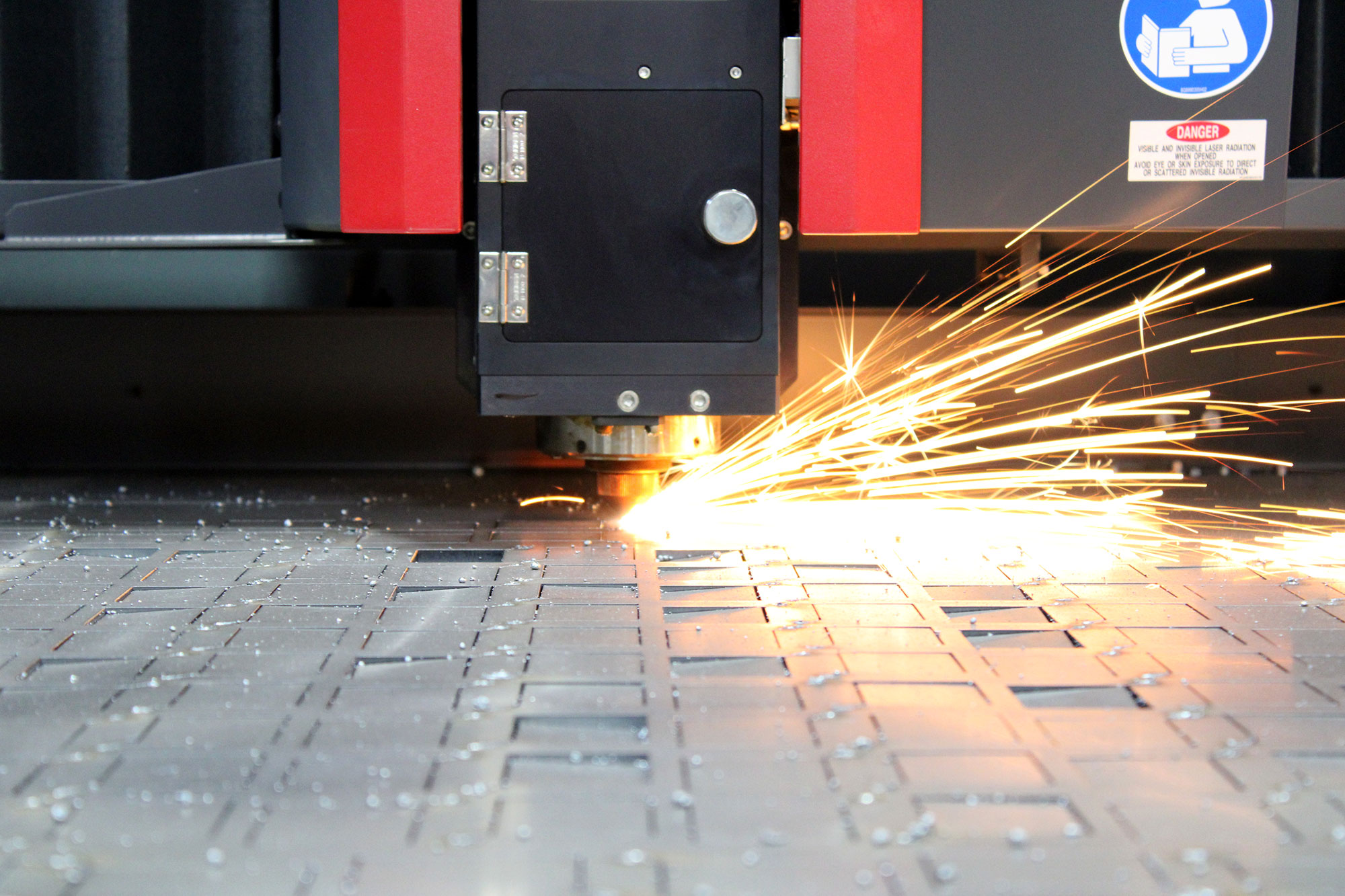

Laser Cutting

Welding

Press Brake

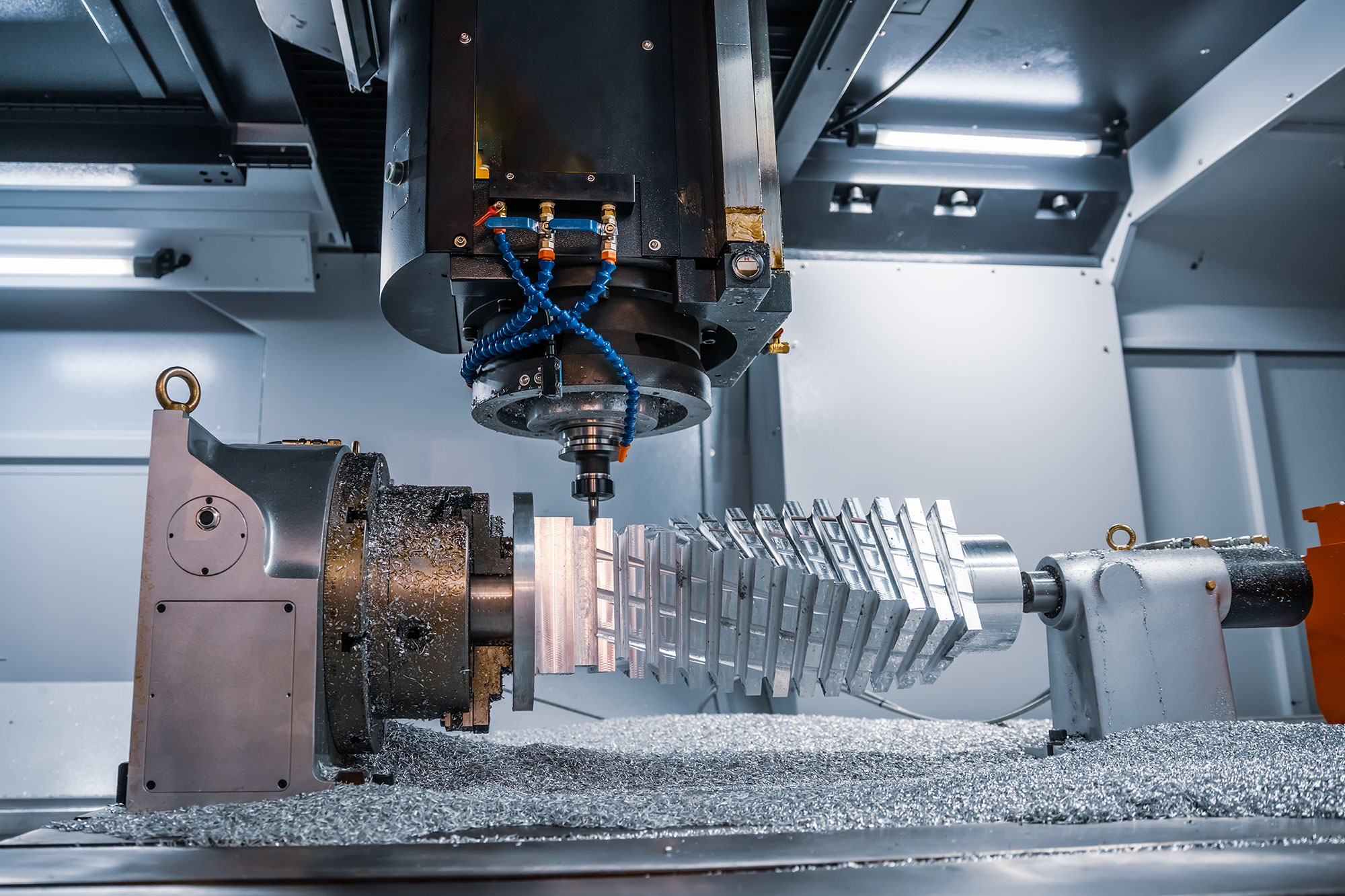

CNC Machining

Assembly

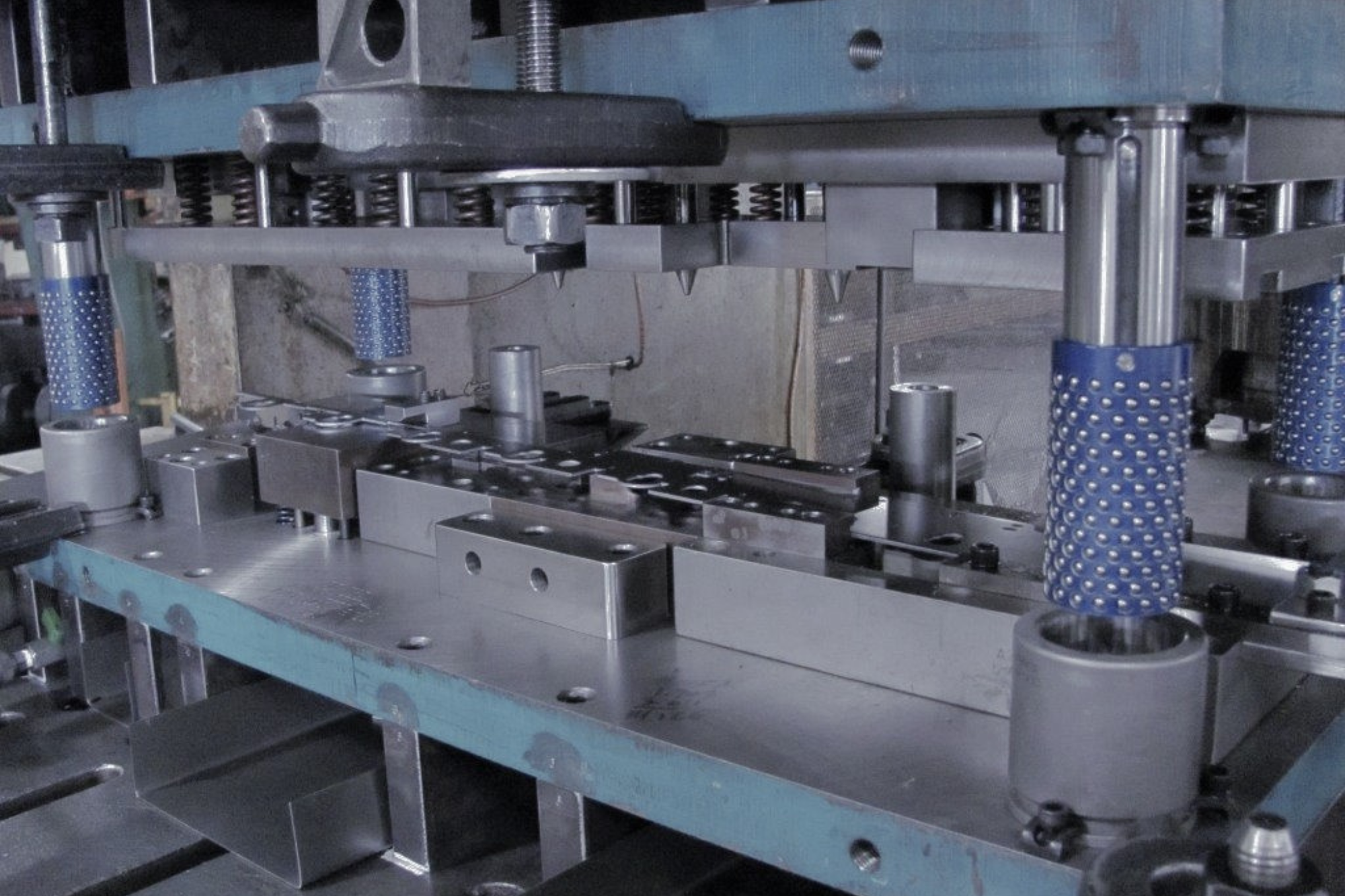

Tool & Die

FFL